The Evolution of Carbon Fiber Car Wrap Vinyl: From Concept to Reality

The concept of carbon fiber car wrap vinyl began to take shape with the increasing popularity of carbon fiber materials in various industries, particularly in aerospace and high-performance sports. Carbon fiber’s lightweight, strength, and futuristic appearance led enthusiasts and automotive professionals to explore its potential applications in the automotive industry.

1. Early Experimentation

In the late 20th century, early experiments involved using carbon fiber sheets and wraps on race cars and high-end sports cars. However, the process was complex and expensive, limiting its widespread adoption.

2. Advancements in Technology

As technology improved, manufacturers began to develop innovative techniques to create carbon fiber car wrap vinyl that could be applied more easily and efficiently on vehicles.

3. Enhanced Materials

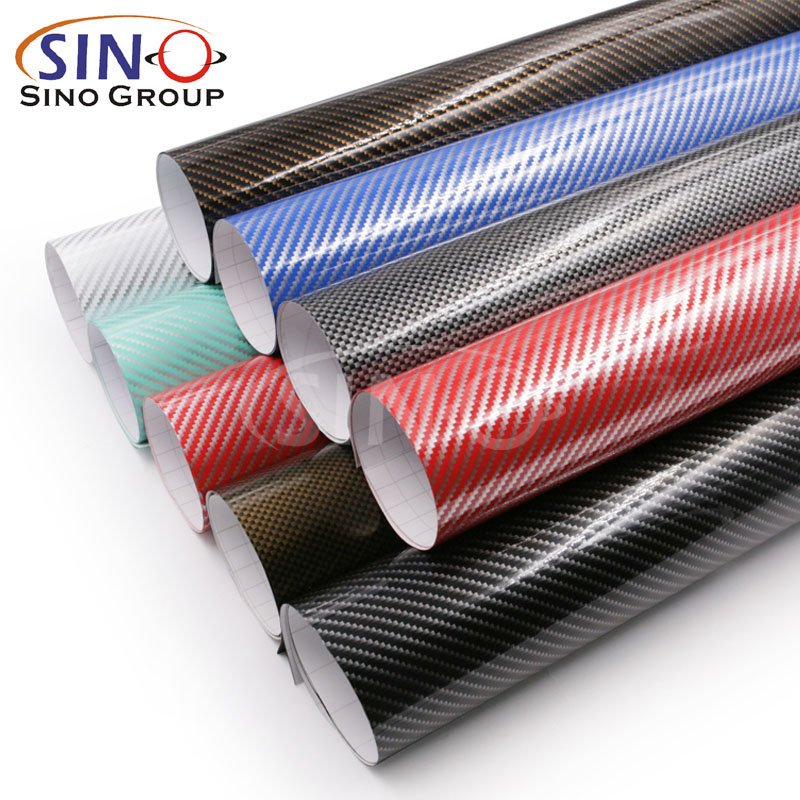

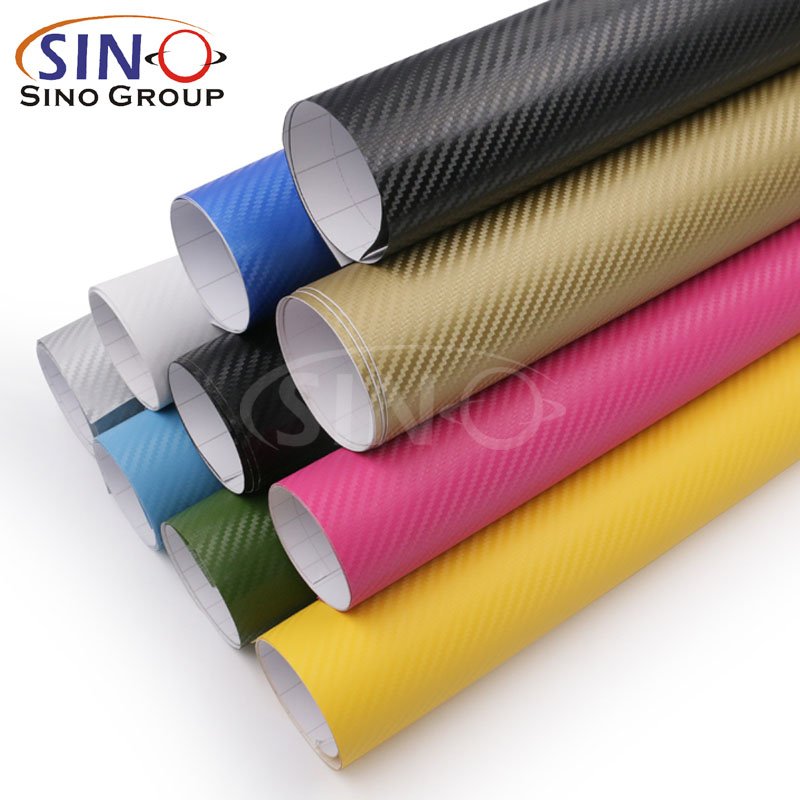

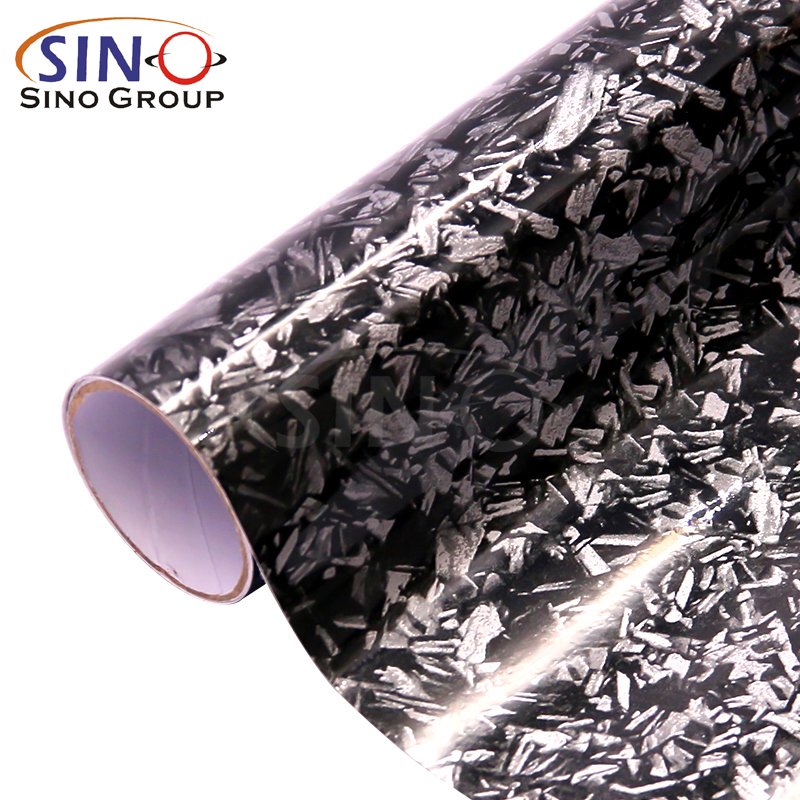

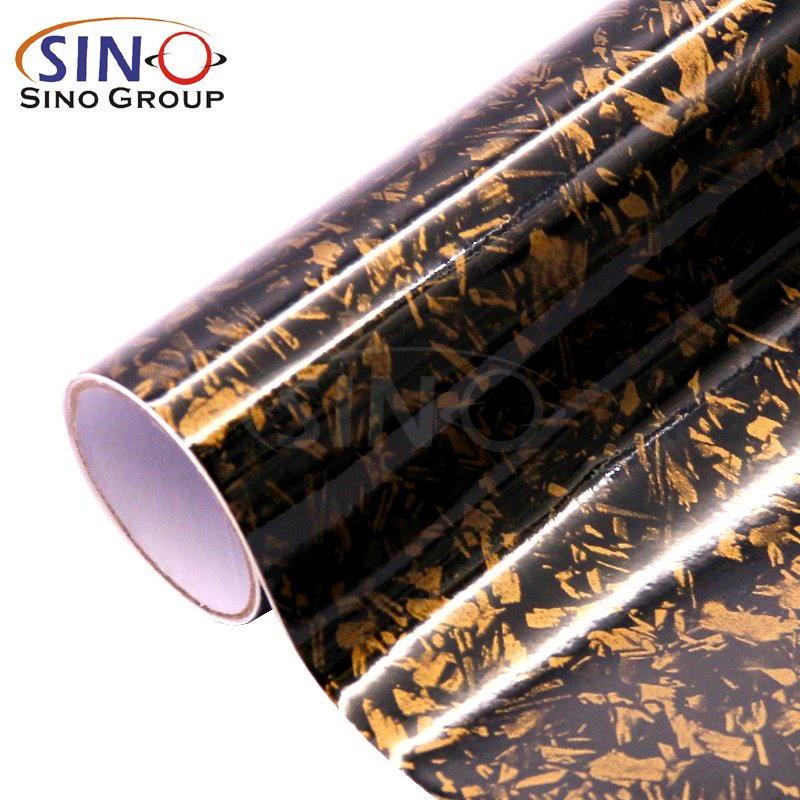

Early versions of carbon fiber car wrap vinyl were limited in terms of color and texture options. Over time, manufacturers perfected the materials, offering a wider range of finishes, patterns, and colors to cater to diverse consumer preferences.

4. Accessibility and Affordability

As demand increased, economies of scale and advancements in production processes made carbon fiber car wrap vinyl more accessible and affordable for car owners.

5. DIY Installation

With the refinement of materials and installation techniques, car enthusiasts and hobbyists could now apply carbon fiber car wrap vinyl themselves, spurring a DIY culture around car customization.

6. Creative Applications

Beyond standard car wrapping, innovative applications of carbon fiber car wrap vinyl emerged, such as interior trim wraps, motorcycle wraps, and even non-automotive uses in home decor and electronics.

7. Performance-Enhancing Properties

Alongside aesthetic benefits, car owners recognized that carbon fiber car wrap vinyl also offered protective properties, safeguarding the original paint from scratches and minor damages.

8. Customization and Personalization

The versatility of carbon fiber car wrap vinyl allowed car owners to express their individuality through unique designs, patterns, and color combinations.

9. Environmental Considerations

As environmental awareness increased, eco-friendly versions of carbon fiber car wrap vinyl, which utilized sustainable materials, gained traction in the market.

10. Mainstream Adoption

The combination of improved technology, affordability, and aesthetic appeal led to the widespread adoption of carbon fiber car wrap vinyl, not only among car enthusiasts but also in the commercial automotive industry.

Today, carbon fiber car wrap vinyl has become an integral part of the automotive customization scene, allowing car owners to transform the appearance of their vehicles easily and cost-effectively. The evolution of this technology continues, with ongoing research and development efforts focused on enhancing durability, introducing new finishes, and exploring alternative applications. As consumer demand evolves, the future of carbon fiber car wrap vinyl looks promising, promising even more exciting possibilities for car owners and enthusiasts worldwide.

Step-by-Step Guide: DIY Installation of Carbon Fiber Car Wrap Vinyl

Installing carbon fiber car wrap vinyl can be a rewarding and cost-effective way to transform your car’s appearance. Follow this step-by-step guide to achieve a professional-looking installation:

Materials Needed

– Carbon fiber car wrap vinyl (ensure you have enough to cover your car’s surface)

– Squeegee or soft application tool

– Heat gun or hairdryer

– Utility knife or precision cutting tool

– Isopropyl alcohol or a gentle cleaning solution

– Microfiber cloth or lint-free towels

Step 1: Prepare Your Car

Thoroughly clean the surfaces you plan to wrap with isopropyl alcohol or a gentle cleaning solution. Ensure the surface is free from any dirt, wax, or debris that could affect adhesion.

Step 2: Measure and Cut the Vinyl

Measure the area you want to wrap using a tape measure and add a few inches to each side for allowance. Use a utility knife or precision cutting tool to cut the carbon fiber car wrap vinyl to the appropriate size and shape.

Step 3: Peel Off the Backing

Peel a small section of the backing from the vinyl to expose the adhesive side. Be careful not to touch the adhesive to avoid leaving fingerprints.

Step 4: Apply the Vinyl

Carefully align the exposed section of the vinyl with the intended area on your car. Start from the center and work your way out, using your hands to press the vinyl onto the surface. The initial alignment is crucial, as it will set the foundation for the rest of the installation.

Step 5: Use a Squeegee

Once you’ve positioned the vinyl correctly, use a squeegee or soft application tool to smooth out the vinyl and remove any air bubbles or creases. Work from the center outward, applying firm, even pressure to ensure proper adhesion.

Step 6: Heat and Stretch

For curved or contoured areas, use a heat gun or hairdryer to gently warm the vinyl. This will make it more pliable and easier to stretch and conform to the curves of your car. Be careful not to overheat the vinyl, as excessive heat can damage it.

Step 7: Trim Excess Vinyl

Trim off any excess vinyl using a precision cutting tool. Pay attention to edges, corners, and tight spaces, ensuring a clean and precise cut.

Step 8: Continue Wrapping

Repeat the process, working in sections, until you have completely wrapped the desired areas of your car.

Step 9: Finishing Touches

Once the vinyl is fully installed, use the heat gun or hairdryer again to apply gentle heat to the entire surface. This step helps the vinyl to set and adhere properly.

Step 10: Final Check

Inspect the entire wrapped surface for any imperfections, air bubbles, or lifted edges. Use the heat gun and squeegee to address any issues and ensure a smooth finish.

Congratulations! You’ve successfully installed carbon fiber car wrap vinyl on your car, elevating its style to a whole new level. With patience and attention to detail, you can achieve a professional-looking DIY installation that will impress others on the road.

The Environmental Benefits of Using Carbon Fiber Car Wrap Vinyl

Using carbon fiber car wrap vinyl offers several environmental benefits compared to traditional automotive painting and other vehicle customization methods. Here are some of the key environmental advantages:

1. Reduced VOC Emissions

Traditional automotive painting involves the use of volatile organic compounds (VOCs) found in many automotive paints. These VOC emissions can contribute to air pollution and have harmful effects on human health. Carbon fiber car wrap vinyl does not emit VOCs during the installation process, making it a more environmentally friendly choice.

2. Water Conservation

Painting a car requires water for cleaning, preparation, and application. Using car wrap vinyl reduces the need for water in the customization process, thus conserving this precious resource.

3. Energy Efficiency

The application of car wrap vinyl requires less energy compared to the automotive painting process. Painting involves multiple steps, such as drying and curing in a controlled environment, which consumes more energy. Car wrap vinyl application is relatively faster and less energy-intensive.

4. Reduced Waste Generation

When painting a car, there is often significant overspray and paint waste, leading to the generation of hazardous materials that require proper disposal. In contrast, car wrap vinyl is precision-cut to fit the vehicle’s contours, resulting in minimal waste.

5. No Harmful Chemicals

Traditional automotive paints contain chemicals like lead, chromium, and other heavy metals, which can be harmful to the environment and health. Carbon fiber car wrap vinyl is free from these toxic substances, making it a safer and greener choice.

6. Minimal Environmental Footprint

Car wrap vinyl has a lower overall environmental impact compared to repainting or refinishing a car. As a result, using carbon fiber car wrap vinyl contributes to a reduced environmental footprint.

7. Longer Vehicle Lifespan

Applying a protective layer of carbon fiber car wrap vinyl can extend the life of the underlying paintwork, helping to reduce the need for repainting or bodywork. This contributes to less frequent use of painting materials and reduces waste over time.

8. Eco-friendly Removal

When the time comes to change the car’s appearance or remove the wrap, it can be done without harmful chemicals or abrasive processes. The removal of car wrap vinyl is typically straightforward and does not damage the underlying paint, reducing the need for repainting and preserving the car’s original finish.

Overall, carbon fiber car wrap vinyl is a more environmentally conscious option for car customization, offering car owners the opportunity to enhance their vehicles’ appearance without causing unnecessary harm to the environment.

Debunking Common Myths about Carbon Fiber Car Wrap Vinyl

Here are some common myths about carbon fiber car wrap vinyl debunked:

Myth 1: Carbon fiber car wrap vinyl is the same as real carbon fiber.

Debunking: While carbon fiber car wrap vinyl is designed to mimic the appearance of real carbon fiber, it is not the same material. Real carbon fiber is a lightweight and incredibly strong material used in various industries, including aerospace and motorsports. Car wrap vinyl is a vinyl-based material with a printed carbon fiber pattern, providing a cost-effective way to achieve the carbon fiber look without the expense and complexity of real carbon fiber.

Myth 2: Carbon fiber car wrap vinyl is fragile and easily damaged.

Debunking: Quality carbon fiber car wrap vinyl is designed to be durable and resistant to normal wear and tear. It can handle exposure to various environmental elements like sunlight, rain, and even light scratches. However, it’s essential to choose a high-quality vinyl and have it professionally installed to ensure optimal durability and longevity.

Myth 3: Carbon fiber car wrap vinyl is difficult to install and requires professional help.

Debunking: While professional installation is recommended for the best results, many car enthusiasts with some experience in car wrapping can install carbon fiber car wrap vinyl themselves. Many vinyl products come with air release channels, making the installation process easier and preventing bubbles or creases.

Myth 4: Carbon fiber car wrap vinyl will damage the car’s paint when removed.

Debunking: A properly installed and removed car wrap vinyl should not damage the underlying paint of the car. High-quality vinyl, when removed correctly, should not leave any adhesive residue or cause paint peeling. However, if the car has pre-existing paint damage or poor paint condition, removing the vinyl may reveal those issues.

Myth 5: Carbon fiber car wrap vinyl is limited to specific car models and shapes.

Debunking: Carbon fiber car wrap vinyl is highly versatile and can be applied to various car models and shapes. It can conform to the contours of most vehicles, including curved surfaces and complex body lines, making it suitable for a wide range of cars.

Myth 6: Carbon fiber car wrap vinyl is permanent once applied.

Debunking: While car wrap vinyl is designed to adhere well to the car’s surface, it is not permanent. It can be removed if desired, allowing car owners to change the wrap or revert to the original paint finish without any lasting effects.

By debunking these myths, car owners can have a better understanding of carbon fiber car wrap vinyl and make informed decisions about whether it’s the right choice for their vehicle customization needs.

Final Words

In conclusion, staying ahead in style has never been more exciting for car owners, thanks to the latest innovations in carbon fiber car wrap vinyl. This versatile and eye-catching material offers a cost-effective way to elevate your car’s aesthetics and make a bold statement on the road. By understanding the science behind its durability and debunking common myths, you can confidently explore the world of carbon fiber car wrap vinyl. Whether you opt for a classic weave pattern or experiment with unique colors and finishes, this cutting-edge technology allows you to customize your ride to reflect your personality and taste. Embrace the trend, unleash your creativity, and let your car become a true reflection of your individuality. With carbon fiber car wrap vinyl, you can transform your vehicle into a head-turning masterpiece that stands out from the crowd and leaves a lasting impression on all who behold it. So, what are you waiting for? Take the leap into the world of carbon fiber car wrap vinyl and make a bold statement on the road today!